The Balanced Calorimeter is a highly specialized testing apparatus specifically designed for the accurate evaluation of air conditioning (AC) units and heat pumps. This advanced instrument precisely measures cooling, heating, and dehumidification capacities. Its designation as “balanced” stems from its operational method, which accurately minimizes heat leakage, thereby enabling exceptionally precise capacity measurements. The critical role of the Balanced Calorimeter in the HVAC industry cannot be overstated, due to its significant contribution to ensuring product quality and efficiency standards.

The High Accuracy and Operating Principle of a Balanced Calorimeter

The significant importance of the Balanced Calorimeter lies in its unmatched ability to deliver highly precise and accurate performance measurements. This accuracy is primarily facilitated by its unique design.

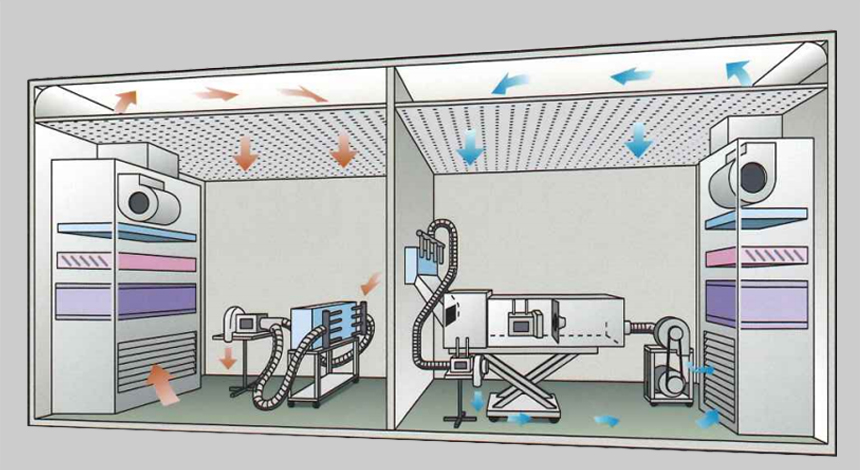

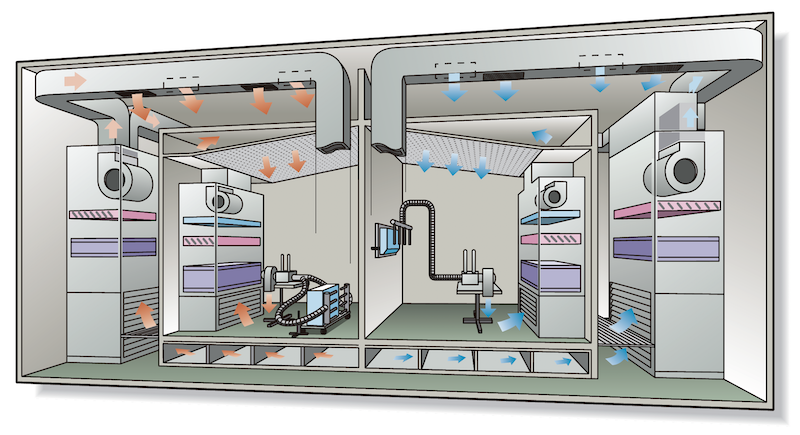

A Balanced Calorimeter consists of two adjacent chambers: an indoor chamber and an outdoor chamber. Both chambers are enveloped by an annular space that independently maintains the same temperature and humidity as the chamber it surrounds. This dual construction is crucial for eliminating temperature differentials and enabling accurate capacity measurement. Furthermore, the temperature, humidity, and airflow within each chamber can be independently controlled, creating an exquisitely controlled testing environment.

The operational principle of the Balanced Calorimeter is founded on the concept of energy balance. Within this system, heat lost by one component is precisely balanced with heat gained by another, perfectly reflecting the principle of energy conservation. This means the thermal input from measuring devices is precisely equated with the AC unit’s thermal capacity. The cooling and dehumidification capacity (in cooling mode), as well as the heating capacity (in heating mode) of the indoor AC unit, are measured directly. This measurement method is ideal because accurate capacity measurement under standard testing conditions is of paramount importance. The accuracy is further enhanced by the fact that the calculation and measurement methods of the Balanced Calorimeter have lower measurement uncertainty compared to psychrometric calorimeters. The Balanced Calorimeter is recognized in the industry for its capability to measure and provide more precise air conditioner rating results, also offering a testing repeatability of 1% and agreement of 2% or better with calibrated test units.

Who Benefits from a Balanced Calorimeter?

The Balanced Calorimeter is an essential tool for various stakeholders within the HVAC ecosystem who require highly accurate performance data for AC units and heat pumps. These parties include:

- Manufacturers of AC Units and Heat Pumps: They utilize this calorimeter to evaluate the performance of various types of room air conditioners (split, window, or wall-mounted), packaged terminal AC units, and packaged terminal heat pumps. This is crucial for compliance testing of manufacturing design samples and for quality control purposes.

- HVAC Research and Development (R&D) Departments: The Balanced Calorimeter is used for HVAC R&D, enabling the development of innovations and improvements in system performance.

- Testing and Certification Institutions or Laboratories: They use this device to conduct HVAC capacity testing and determine the most accurate ratings for AC units. The Balanced Calorimeter complies with various international testing standards, such as JIS C 9612, ISO 5151:2010, ANSI/ASHRAE Standard 16–2016, and AHRI Standard 340/360:2015. This compliance is essential to ensure that test results are widely accepted globally.

- Parties Conducting Energy Audits and Compliance: The Balanced Calorimeter is also used for energy audit compliance purposes, helping to verify the energy efficiency of HVAC systems.

Summary

In short, the Balanced Calorimeter is highly essential due to its ability to measure the cooling and heating capacity of HVAC units with superior accuracy and precision, allowing for controlled and standardized testing conditions. With a verifiable cooling capacity range from 6,000 to 42,000 Btu/hour, and the capability to maintain specific operating conditions (e.g., indoor chamber 45°F to 100°F DB and outdoor chamber 10°F to 120°F DB), the Balanced Calorimeter, with all its advantages, becomes an irreplaceable tool for product development, quality control, certification, and energy auditing within the HVAC industry.

Satake Fimar Indonesia possesses deep expertise, consistent professionalism, and extensive experience as a leading HVAC Contractor. We are experienced in designing, procuring, installing, and commissioning advanced Balanced Calorimeter facilities, ensuring every detail meets the highest international standards for precision and reliability.

Ready to enhance your HVAC testing capabilities? Contact Satake Fimar Indonesia now for a comprehensive consultation! WhatsApp: +6282310043646.