Beyond the good reputation as a reliable HVAC contractor with extensive experience, Satake Fimar Indonesia also own deep expertise in designing, building, and providing a range of industrial refrigeration systems, including Cold Storage, Blast Freezing, Chillers, Freeze Drying, and Reefers.

To differentiate from HVAC, specifically refrigeration by definition is a technique used to maintain a temperature below ambient levels in a controlled manner. The objective is to preserve products, regulate chemical reactions, or to ensure the optimal performance of equipments. In the modern era, refrigeration technology has become critical for various vital industries that rely on precise temperature control for operational continuity, safety, and product qualiti.

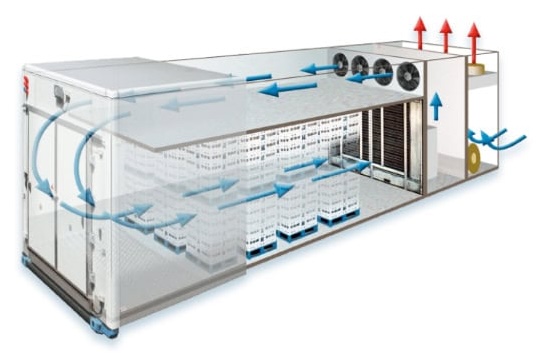

Cold Storage

Cold storage is a cooling warehouse for storing fresh products like fruits, vegetables, meat, and dairy to extend their shelf life before distribution. Cold storage can significantly decrease food waste or goods decay and at the end of the day increasing cost efficiency.

Blast Freezing

Blast freezing is a system to provide an extremely rapid freezing technique for frozen foods such as fish, ice cream, and processed foods, which helps preserve their texture, flavor, and nutrients.

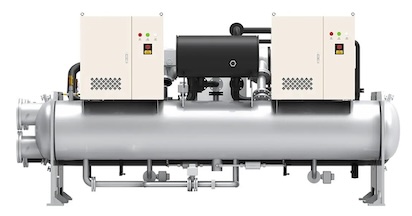

Chillers

Chillers are practically used to cool water or other raw materials which then used to cool building or during the production of soft drinks, or fruit juices before bottling.

Freeze Drying

Freeze drying technique is a process that uses cooling to preserve materials, especially delicate biological and pharmaceutical products, by removing water while maintaining their original properties, structure, and quality this is used for freeze products (e.g., vaccines, serums, or pharmaceutical ingredients) before they are dried in a vacuum.

Refrigerated Containers (Reefers)

Reefers are refrigeration systems installed on trucks, ships, and trains to transport products that require low temperatures, such as frozen foods, pharmaceuticals, or chemicals.

Refrigeration Applications Across Industries

Refrigeration also has critical applications across various industries:

- Food and Beverage Industry:

- Warehouses for storing fresh produce like fruits, vegetables, meat, and dairy to ensure their longevity before distribution.

- Blast Freezing for foods like fish, ice cream, and processed meals to maintain their texture, flavor, and nutritional value.

- Beverage Production: Chillers are used to cool water or other raw ingredients during the production of soft drinks, or fruit juices before bottling.

- Chemical and Pharmaceutical Industry:

- Strict temperature control for storing reactive chemicals or medicines that can degrade at room temperature.

- Refrigeration is used to manage the temperature of chemical reactors to control reaction rates and prevent hazardous conditions, particularly for exothermic (heat-generating) processes.

- Freeze Drying to freeze products (e.g., vaccines, serums, or pharmaceutical ingredients) before they are dried under a vacuum.

- Oil and Gas Industry:

- Natural Gas Liquefaction (LNG) cooling technique is used to chill natural gas until it becomes a liquid (around -162°C), reducing its volume for easy transport.

- Refrigeration is used at oil refineries in various distillation and separation processes to purify petroleum products.

- Construction Industry: The chilling of water or concrete aggregates is used in large-scale construction projects (e.g., dams) to control hydration heat, prevent cracking, and enhance the concrete’s strength.

- Manufacturing Industry:

- Machine Cooling (Chiller Systems) are used to cool fluids (oil, water) flowing through industrial machinery to prevent overheating and ensure optimal performance, especially for plastic injection molding machines, laser cutting machines, and CNC machines.

- Product Testing: Controlled test rooms or environmental chambers use refrigeration systems to simulate extreme conditions (hot and cold) to test product durability.

- Data Centers: Precision Air Conditioning (PAC) systems are used to maintain stable temperature and humidity in server rooms, preventing overheating of thousands of computers operating non-stop and preserving data integrity.

- Transportation: Reefer trucks and containers are equipped with refrigeration systems to transport temperature-sensitive products like frozen foods, pharmaceuticals, or chemicals.

As a leading expert in the HVAC and Refrigeration industry, PT. Satake Fimar Indonesia has comprehensive expertise to design, build, and implement complex, customized industrial refrigeration solutions. We offer an end-to-end approach, ensuring every system is perfectly designed and implemented to meet our clients’ operational needs for maximum efficiency and reliability.

A clear proof to our capabilities is our successful construction of a specialized Cooling Tunnel for our esteemed client, Meiji. This Cooling Tunnel was designed to accelerate the product cooling process efficiently and hygienically, a vital application in the food industry that demands both speed and high hygiene standards. With Satake Fimar Indonesia, you get a reliable, efficient, and precise refrigeration solution that guarantees product integrity, operational safety, and business efficiency.