Traditionally, the common method for evaluating air conditioners (AC) has involved measuring their capacity under fixed temperature and humidity test conditions. While still widely used in most countries, this approach has limitations in reflecting how AC systems truly operate in real-world environments. Over the years, evaluation methods that account for seasonal temperature variations, such as APF (Annual Performance Factor), CSPF (Cooling Seasonal Performance Factor), and HSPF (Heating Seasonal Performance Factor), have gradually been adopted.

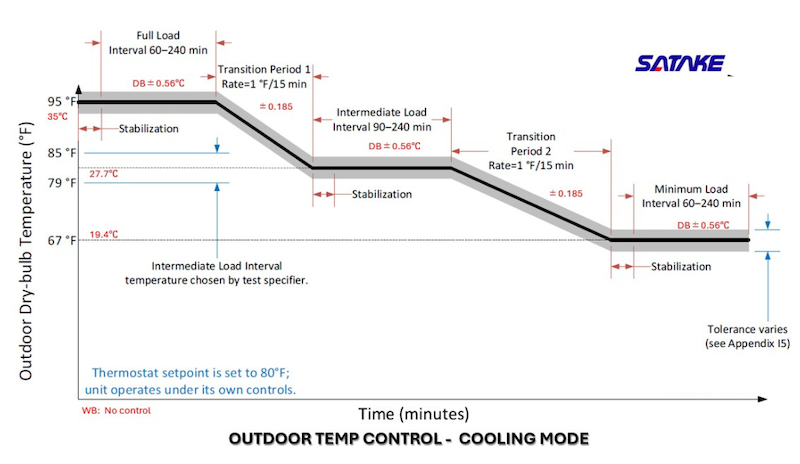

A significant advancement in air conditioner evaluation is the new Control Verification Procedure (CVP) , introduced recently under the U.S. Department of Energy (DOE) regulations and based on the revised AHRI 210/240 standard. CVP is a new testing method that considers both indoor thermal loads and outdoor weather conditions. It enables the indoor unit to operate freely in response to simulated real-world conditions during testing, while outdoor conditions are varied to assess the AC’s control functions.

This stands in stark contrast to conventional steady-state methods, where test room conditions are maintained within narrow operating tolerances, and AC/HP systems are manually controlled to operate at fixed compressor speeds and airflow rates.

Satake’s software, integrated into our psychrometric rooms, is equipped with advanced capabilities to automatically adopt the testing scenarios required by CVP methods. This integration offers a high degree of accuracy and precision, and significantly eliminates the need for manual adjustments, which are often time-consuming and prone to human error. This ensures optimal operational efficiency and superior reliability of testing results.

Here are three key advantages of using the CVP method for improving air conditioner evaluation accuracy:

1. More Realistic and Representative Testing

Conventional methods often lock parameters like compressor speed and airflow rate, which may not accurately reflect how a unit operates in actual conditions. CVP, conversely, focuses on the “native controls” of the unit’s control system, allowing it to automatically manage critical parameters such as compressor speed, fan speed, and valve position in response to simulated conditioning loads. For instance, if an AC unit in cooling mode cannot meet a virtual load, the simulated room temperature will genuinely rise, mirroring a real-world scenario. This approach provides a more precise representation of the AC system’s performance in the field, ensuring that manufacturer performance claims truly reflect real-world operation and verifying that fixed speed settings used in regulatory tests are representative of native control operation.

2. Enhanced Compliance Assessment and Enforcement

CVP is designed as a primary tool for audit, assessment, and compliance enforcement testing by the DOE. While manufacturers are not mandated to perform CVP when rating their products, this method ensures that the fixed speed settings used for certification testing align with the native control operation. This capability allows the DOE to verify a system’s compliance with variable-capacity compressor system definitions. The expectation is that manufacturers will proactively use CVP internally to evaluate the fixed speed settings employed for their variable-speed product certification testing. Consequently, CVP clarifies how the DOE will conduct enforcement testing, providing clarity to the industry.

3. Improved Industry Consensus and Standardization

The development and integration of CVP into the latest industry standards, such as AHRI 210/240-2024 and AHRI 1600-2024, signify a substantial industry consensus. The DOE is actively incorporating these standards into its federal test procedures, leading to better harmonization with industry standards. This step reduces the burden on manufacturers by eliminating the need for separate testing procedures and offers a standard procedure for manufacturers to validate their “normal” operating settings. CVP has also been included in other standards like AHRI 1230-2021 and ENERGY STAR for VRF systems and other heat pumps, demonstrating its broad acceptance and relevance.

In conclusion, the transition towards CVP-based AC evaluation methods marks a significant step forward in ensuring that energy efficiency assessments are more accurate and representative of real-world performance. By enabling systems to operate under their native controls and considering varying environmental conditions, CVP not only enhances the validity of performance claims but also serves as a robust enforcement tool and represents a collaborative industry effort towards better standardization.

Satake Fimar Indonesia possesses deep expertise, consistent professionalism, and extensive experience in the HVAC industry, particularly in understanding and implementing cutting-edge evaluation methodologies like CVP. Our team is highly skilled in interpreting complex standards and applying advanced testing procedures to ensure your HVAC systems meet the highest benchmarks for performance and efficiency. We are dedicated to delivering solutions that not only comply with the latest regulations but also set new standards for quality and reliability. For expert consultation on HVAC system evaluation, testing, or any related services, contact Satake Fimar Indonesia now via WhatsApp at 082310043646.